Machine vision

Our solutions from individual object inspection to turnkey inspection stations.

The technical implementation of automated monitoring of your production processes using image processing (2D/3D) covers a wide range of services. Especially for complex tasks. Thanks to our experience, we can offer you extensive assistance in integrating the optimal visual measurement technology into your existing or future production facilities.

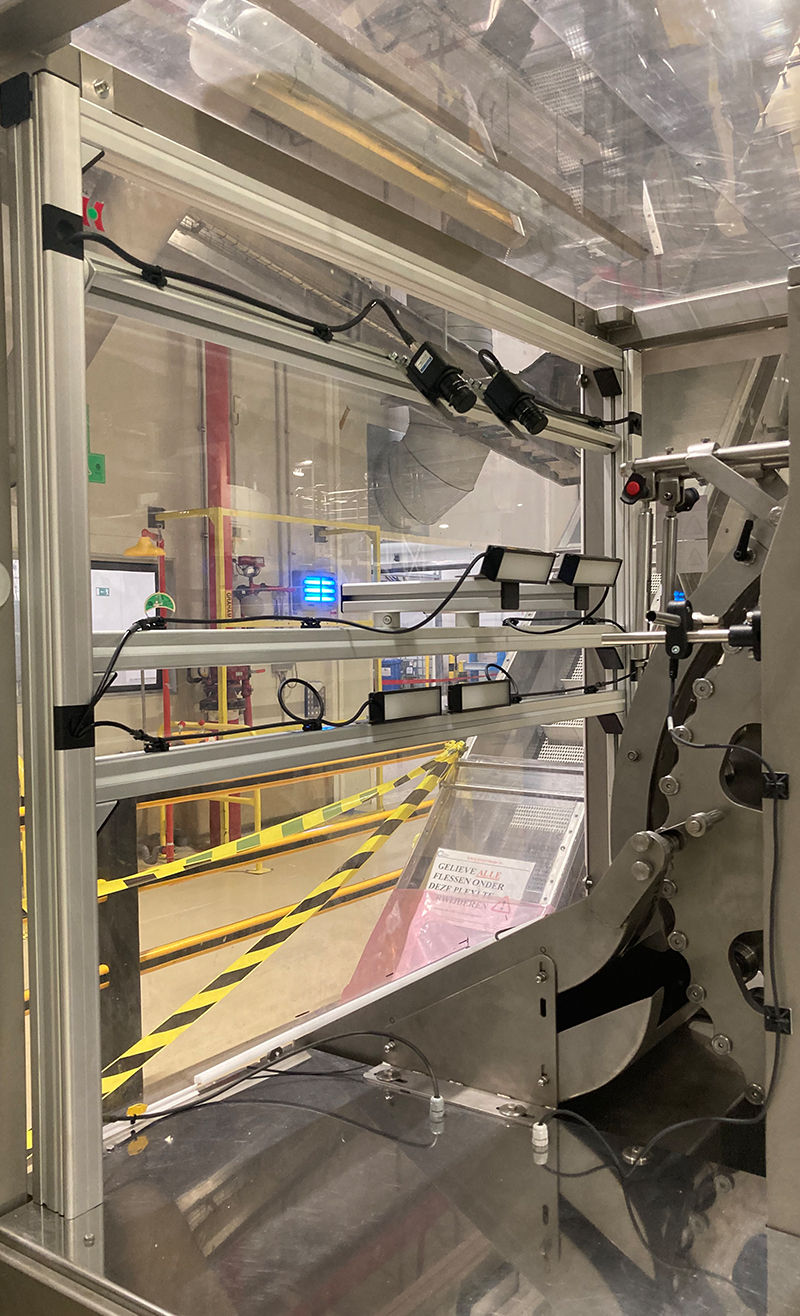

Machine vision in general refers to the use of industrial cameras, lenses, and lighting to perform automated, visual inspection of manufactured products. Machine vision provides a fast, reliable way to inspect parts inline. With machine vision, every part coming down a high-speed line can be imaged and inspected to ensure 100% quality control. In the factory processes, machine vision can automate various inspections such as appearance inspections that check defects and faults, presence-absence checks, product type verifications, measurements and code readings.

Machine Vision

Our solutions from individual object inspection to turnkey inspection stations.

The technical implementation of automated monitoring of your production processes using image processing (2D/3D) covers a wide range of services. Especially for complex tasks. Thanks to our experience, we can offer you extensive assistance in integrating the optimal visual measurement technology into your existing or future production facilities.

Electromechanical engineering

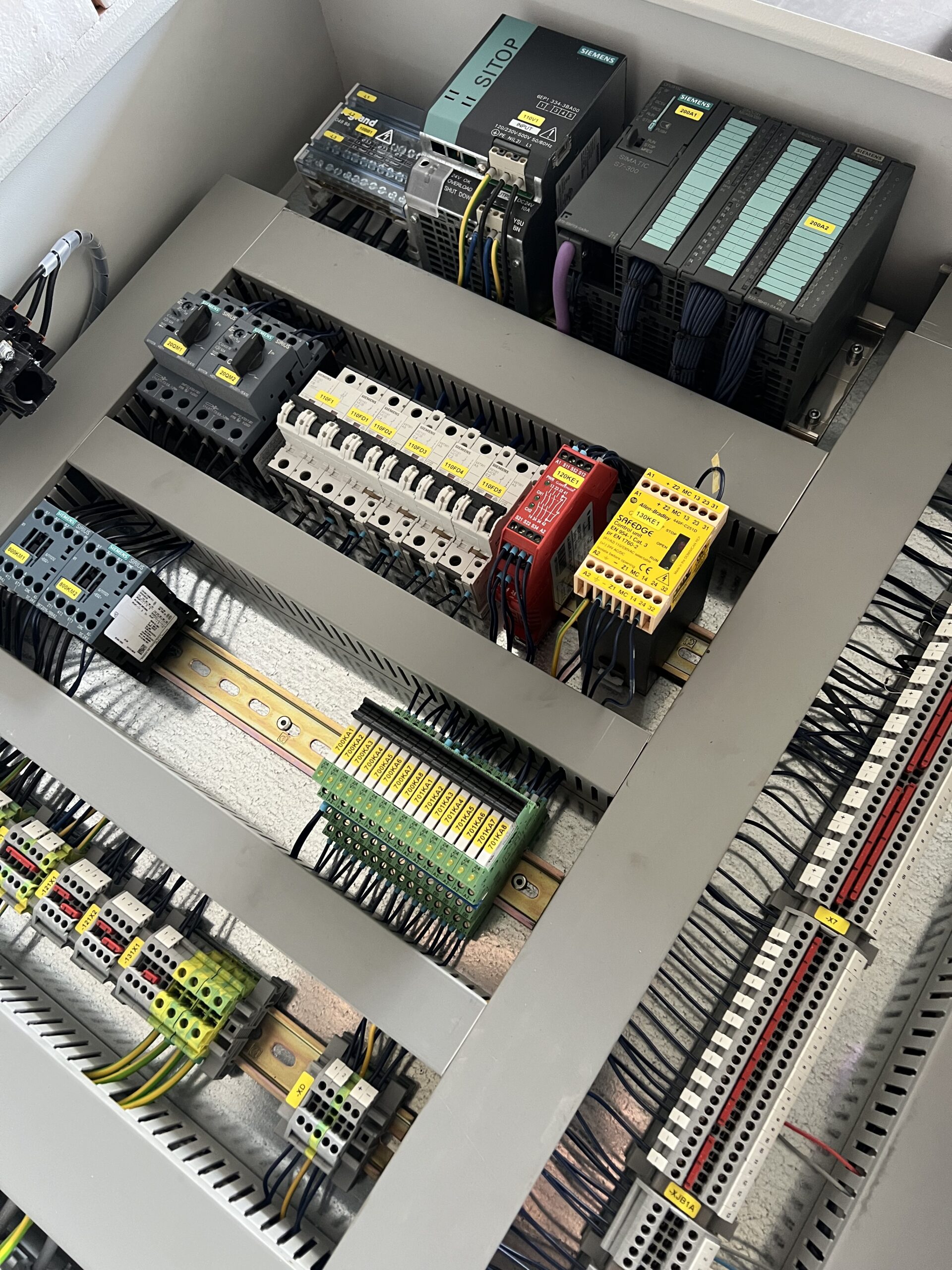

We design your project from idea to a fully developed concept. This through mechanical 3D drawings as well as electrical diagrams. Afterwards we engineer this with our mechanical and electrical in-house knowledge. During this phase we also provide the appropriate documentation and CE marking for your installation.

The concepts go from standard in-line retrofits on existing machines to dedicated stand-alone or in-line inspection stations.

Electromechanical Engineering

We design your project from idea to a fully developed concept. This through mechanical 3D drawings as well as electrical diagrams. We then work this out ourselves with our mechanical and electrical in-house knowledge. During this phase we also provide the appropriate documentation and CE marking for your installation.

The concepts go from standard in-line retrofits on existing machines to dedicated stand-alone or in-line inspection stations.

Industrial automation

Today, when we talk about machines, industrial automation is one of the most important pillars.

When we integrate our machine vision in your production machine we have to communicate with the existing PLC. This is very important to get the most out of all the machine vision functionalities. This can go from activating rejects or flagging a series of bad inspections, as well as counting the OK/NG parts for easy traceability. In case of product format changeover we can also trigger a new inspection program. All this in accordance with customer requirements.

Industrial Automation

Today, when we talk about machines, industrial automation is one of the most important pillars.

When we integrate our machine vision in your production machine. This means that we have to communicated with the existing PLC. This is very important to get the most out of all the machine vision functionalities. This can go from activating rejects or flagging a series of bad inspections. But also counting the OK/NG parts for easy traceability. In case of product format change over we can also trigger a new inspection program. All this in accordance with customers requirements

Optimizations

We help to optimize if you already have existing machine vision in your production process that needs program or hardware improvements. In case of outdated machine vision technologies, we can also help with retrofits to get the inspection fully functional and back up-to-date with todays technologies.

Optimization

If you already have existing machine vision in your production process that needs program of hardware improvements. In case of outdated machine vision technologies we can also help with retrofits to get the inspection fully functional and back up to date with todays technologies.